In a world where gadgets seem to multiply faster than rabbits, consumer electronics testing is the unsung hero ensuring that not all tech is created equal. Imagine buying the latest smartphone only to discover it’s as reliable as a chocolate teapot. That’s where rigorous testing comes into play, saving consumers from tech disasters and ensuring products live up to their shiny promises.

Table of Contents

ToggleOverview of Consumer Electronics Testing

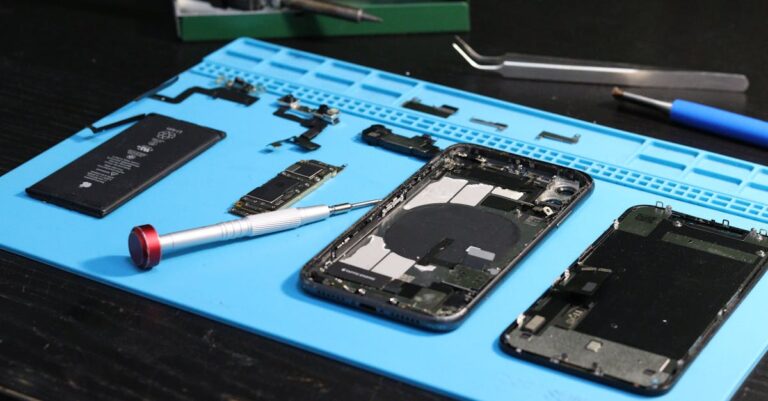

Consumer electronics testing encompasses various evaluations aimed at ensuring product quality and reliability. This process involves multiple stages, including design validation, performance testing, and compliance checks. Manufacturers frequently conduct these tests to meet industry standards, ensuring devices operate as intended.

Performance testing assesses how well gadgets function under various conditions. For example, smartphones undergo drop tests, battery life evaluations, and connectivity checks. These measures identify potential weaknesses that could lead to user dissatisfaction.

Safety testing plays a crucial role in ensuring devices meet regulatory requirements. Devices must pass environmental tests to confirm they’re safe for consumer use. This includes assessments for overheating, electrical safety, and materials that could cause harm.

Durability testing evaluates a product’s ability to withstand wear and tear. Electronics are subjected to extreme temperatures, humidity levels, and physical stress. Such testing helps manufacturers identify any design flaws that may compromise a device’s lifespan.

Moreover, software testing ensures that embedded systems operate without glitches. Developers check for bugs and compatibility issues across different platforms. Proper software testing enhances user experience and minimizes the risk of malfunction.

Finally, consumer feedback on tested devices can guide further improvements. Companies often gather insights from early adopters to refine product features. This iterative process promotes continuous improvement and customer satisfaction.

Consumer electronics testing serves as a safeguard for both manufacturers and users, guaranteeing high-quality, reliable products in the market.

Importance of Consumer Electronics Testing

Consumer electronics testing plays a vital role in ensuring product reliability and safety in a fast-paced technological environment. By implementing thorough testing procedures, the industry aligns products with consumer expectations and regulatory demands.

Quality Assurance

Quality assurance encompasses various testing phases to verify that electronic devices perform as intended. Manufacturers utilize this process to identify defects before reaching the market. Performance evaluations check functionality under different conditions, ensuring users experience consistent operation. Design validation confirms that a product meets specified requirements. Additionally, durable components enhance longevity, reducing the frequency of replacements. The overall outcome of rigorous quality assurance practices is fewer product failures, promoting customer trust in fulfilled promises.

Safety Standards

Safety standards guarantee that consumer electronics adhere to essential safety regulations. Regulatory bodies establish these standards to reduce risks such as electrical hazards and fire threats. Testing laboratories conduct assessments to verify conformity to these regulations. Evaluating components and materials ensures they pose no harm to users. Meeting safety criteria not only protects consumers but also shields manufacturers from liability issues. By prioritizing safety, the industry fosters confidence in the products available to consumers.

Types of Consumer Electronics Testing

Consumer electronics testing encompasses various specialized evaluations to ensure product quality and safety. Each type focuses on different aspects of a device’s functionality and regulatory compliance.

Functional Testing

Functional testing verifies that all features of a device operate correctly. This process checks whether each component performs as designed, from touchscreens responding to user input to cameras capturing clear images. Testing teams execute a series of scenarios to simulate real-world conditions. They assess user interfaces and connectivity with other devices. The goal is to confirm that the product delivers expected functionalities without glitches or failures.

Performance Testing

Performance testing evaluates how well devices operate under varying conditions. Factors such as speed, responsiveness, and battery life come into play during these assessments. Engineers simulate stress by running multiple applications simultaneously. They measure the device’s ability to handle tasks without compromising performance. Metrics such as load time and energy consumption are crucial for consumer satisfaction. This process ensures that gadgets can endure typical use without degrading in performance over time.

Compliance Testing

Compliance testing checks if products adhere to relevant standards and regulations. Companies must ensure devices meet safety, electromagnetic compatibility, and environmental requirements. Regulatory bodies establish these benchmarks to protect consumers and promote market fairness. During this testing phase, laboratories examine devices for electrical safety and improper emissions. They verify adherence to local and international guidelines, reducing potential risks associated with their use. Compliance testing ultimately enhances consumer trust and accountability in the electronics market.

Tools and Equipment Used in Testing

Testing consumer electronics necessitates various specialized tools and equipment. These instruments ensure accurate assessments of performance, safety, and compliance.

Test Equipment

- Multimeter

Multimeters measure voltage, current, and resistance in electrical components. They’re essential for diagnosing issues in circuit boards and battery systems.

- Oscilloscope

Oscilloscopes visualize electrical signals over time. Engineers use them to analyze waveforms, providing insights into device performance and functionality.

- Spectrum Analyzer

Spectrum analyzers evaluate the frequency spectrum of signals. They assist in examining wireless communication devices, ensuring compliance with regulatory standards.

- Environmental Chambers

Environmental chambers simulate extreme temperatures and humidity levels. Devices undergo testing to assess how environmental conditions affect their performance and durability.

Safety Testing Tools

- Electricity Safety Analyzer

This tool tests insulation resistance and measures leakage current. It verifies that devices meet safety regulations, reducing electrical hazards.

- Flame Test Apparatus

Flame testers assess the flammability of materials used in electronic devices. This equipment prevents the use of potentially hazardous materials in consumer products.

Performance Testing Equipment

- Load Testers

Load testers evaluate how devices perform under various loads. They measure system responses during peak operational conditions, ensuring reliability and functionality.

- Automation Testing Tools

Automation tools expedite software testing across devices. Automated scripts execute tasks, identify bugs, and check compatibility across different platforms.

Compliance Testing

- Regulatory Compliance Software

This software streamlines the compliance testing process, ensuring that devices adhere to industry standards. By managing documentation and tracking testing results, manufacturers enhance accountability.

Incorporating these tools and equipment into consumer electronics testing strengthens the overall quality assurance process and enhances consumer trust in the technology market.

Challenges in Consumer Electronics Testing

Consumer electronics testing faces several substantial challenges despite its critical importance. Firstly, rapid technological advancements create hurdles in keeping testing protocols updated. Manufacturers often release new devices with unique features that require specific assessments, making it difficult to maintain consistent testing practices.

Moreover, ensuring compliance with a multitude of ever-changing regulations poses challenges. Regulatory bodies frequently update standards, which can impact various aspects of safety and performance testing. Manufacturers must stay informed about these changes to avoid compliance issues.

Additionally, the complexity of modern devices adds to the challenge. Many consumer electronics integrate advanced technologies, leading to intricate interactions between components. Testing these interactions demands sophisticated methodologies to uncover potential issues that standard tests may overlook.

A limited budget for testing can restrict a manufacturer’s ability to perform comprehensive evaluations. Some companies prioritize cost reduction, often sacrificing thorough testing processes. This approach increases the risk of defects and safety hazards in the final product.

Furthermore, the time constraints associated with product launches can lead to rushed testing. Market competition drives manufacturers to release products quickly, often resulting in inadequate testing phases. This scenario increases the likelihood that faulty devices will reach consumers.

Lastly, the growing emphasis on sustainability introduces new testing criteria. As manufacturers aim to use eco-friendly materials and practices, testing must account for environmental impacts. This focus emphasizes the need for a balance between innovative product features and eco-conscious standards, posing yet another layer of complexity in consumer electronics testing.

Consumer electronics testing stands as a vital element in ensuring product reliability and safety. By adhering to rigorous testing protocols manufacturers can enhance consumer trust and satisfaction. The dynamic nature of technology demands that testing practices evolve to meet new challenges while maintaining high standards.

As the market continues to innovate it’s essential for both manufacturers and consumers to prioritize thorough testing. This commitment not only safeguards users but also fosters a culture of accountability within the electronics industry. Ultimately, effective consumer electronics testing paves the way for a future filled with dependable and high-quality devices.