Iron bacteria can turn your crystal-clear well water into a rusty nightmare. If you’ve ever caught a glimpse of that unsightly orange slime or tasted a metallic tang, you know it’s time to take action. Luckily, shocking your well is like giving it a much-needed spa day, ridding it of those pesky bacteria and restoring its freshness.

Table of Contents

ToggleUnderstanding Iron Bacteria

Iron bacteria thrive in environments rich in iron and oxygen, often present in groundwater. These microorganisms lead to various issues, including discoloration and taste in well water.

What Are Iron Bacteria?

Iron bacteria are naturally occurring microorganisms that oxidize dissolved iron. They form colonies, creating a rust-colored slime, often mistaken for sediment. Found in soil and groundwater, they can proliferate in water systems, impacting domestic wells and industrial water supplies. Their presence usually indicates a higher concentration of iron, raising concerns for water quality.

Symptoms of Iron Bacteria Presence

Several symptoms signal iron bacteria contamination. Unpleasant odors commonly arise, reminiscent of rotten eggs or sewage. Discolored water appears with reddish or brownish hues, indicating rust deposits. Developing orange or brown slime around fixtures and inside pipes is another telltale sign. Metallic tastes in water often accompany these visible symptoms, detracting from the overall quality. Recognizing these indicators early maintains well water clarity and safety.

Preparing to Shock Your Well

Ensuring safety and gathering the right materials are vital steps before shocking a well for iron bacteria. Proper preparation leads to effective treatment and improved water quality.

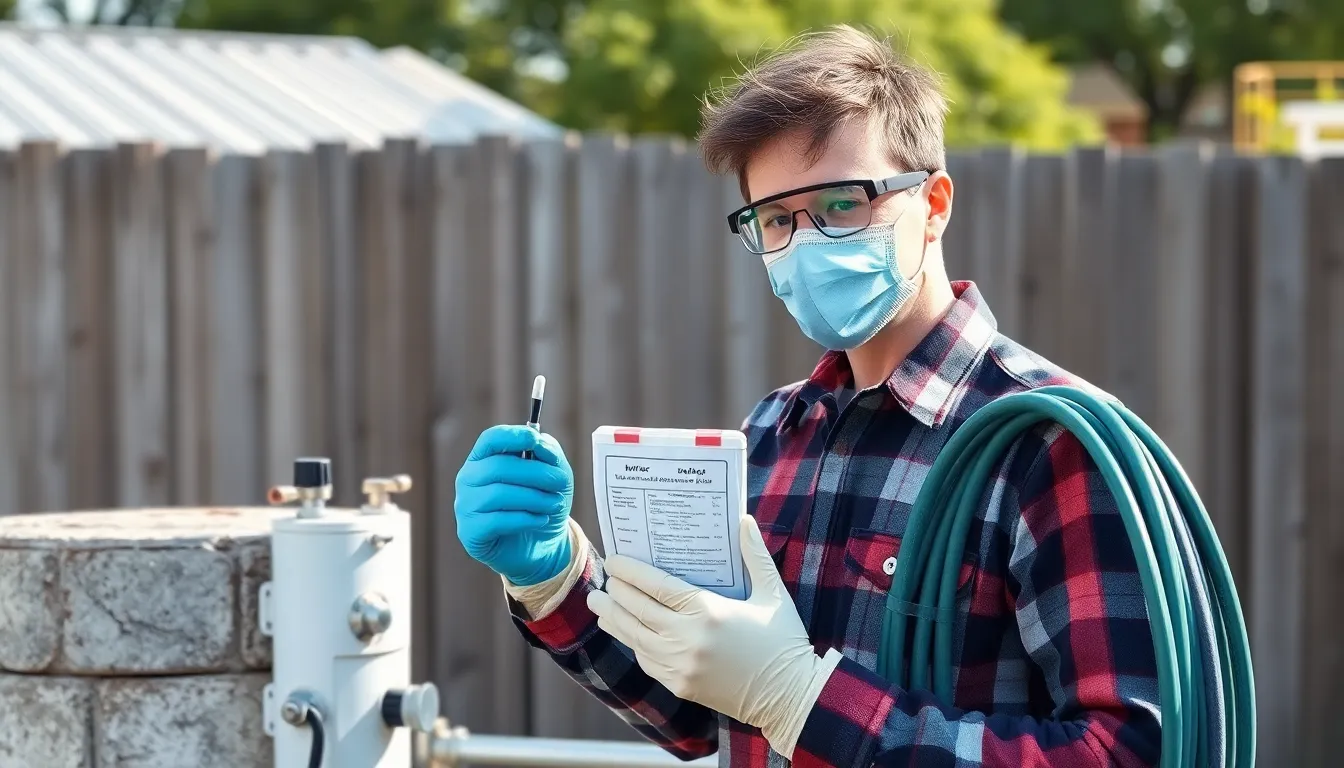

Safety Precautions

Always prioritize safety when working with well water. Protective gear such as gloves, goggles, and a mask can shield against harmful chemicals. Ventilation is crucial; work outdoors or in a well-ventilated area to avoid inhaling fumes. If safety instructions from chemical manufacturers are unclear, read them carefully before proceeding. It’s essential to keep children and pets away from the area during treatment. Checking the well for any structural issues or leaks beforehand can prevent further complications.

Necessary Equipment and Materials

Gathering the right equipment ensures a successful well shocking process. Water testing kits help assess the presence of iron bacteria. A chlorine bleach solution is commonly used, with a concentration of 5% to 7% sodium hypochlorite preferred. A garden hose enables the application of the bleach solution directly into the well casing. A bucket aids in measuring the bleach accurately before pouring. Don’t forget a stir stick for mixing purposes. A safe storage container keeps leftover solutions secure and out of reach. Collecting this equipment in one place streamlines the process and prepares for the infusion of chlorine.

Steps to Shock a Well for Iron Bacteria

Shocking a well for iron bacteria involves several crucial steps to ensure effectiveness. Each step plays a vital role in restoring water quality and safety.

Disconnecting the Power Supply

Start by disconnecting the well’s power supply. This action prevents any electrical hazards during the shocking process. Most wells utilize submersible pumps that need to be powered off to ensure safety. Turning off the circuit breaker is necessary to avoid accidents while handling equipment. Additionally, confirming that no one is using water during treatment helps maintain the desired chemical concentration.

Cleaning and Disinfecting the Well Components

Clean well components thoroughly before proceeding. Removing any visible slime or debris reduces bacteria presence and facilitates better chlorine absorption. Use a cleaning brush to scrub down the well casing and any accessible surfaces. Disinfecting components with a diluted bleach solution enhances the shocking process. Rinsing these areas well ensures no residual cleaning chemicals impact water quality negatively.

Adding Shock Chlorine

Add a shock chlorine solution following manufacturer guidelines. Measuring the appropriate amount of chlorine is essential for effective results. Pour the solution directly into the well using a garden hose or bucket. Mixing the chlorine with water helps distribute it evenly throughout the well. Circulating the solution by running the pump for a short period maximizes contact with iron bacteria, ensuring thorough treatment.

Post-Shocking Procedures

Post-shocking procedures are vital for restoring and maintaining well water quality. Following the shocking process, testing the water ensures that iron bacteria levels are effectively reduced.

Testing Water Quality

Testing water quality after shocking is crucial. Use a reliable water testing kit to evaluate the presence of iron bacteria and other contaminants. Testing should happen within 24 hours after treatment to ensure accurate results. With tests measuring levels of bacteria, pH, and other contaminants, results provide insight into water safety. A reduction in iron concentration signals successful chlorine treatment. Repeat testing at regular intervals promotes consistent quality checks, ensuring water remains safe for use.

Monitoring for Recurrence

Monitoring for recurrence helps in proactive water management. Regular inspections of well water quality assess for signs of iron bacteria return. Keeping an eye out for odors, discoloration, or slime can indicate a problem. If issues arise, shock treatment can be repeated promptly. Implementing a routine maintenance schedule, such as biannual checks, can greatly reduce future bacteria growth. It promotes long-term stability and ensures users maintain clean, clear water for drinking and household use.

Addressing iron bacteria in well water is essential for maintaining its quality and safety. By properly shocking the well, individuals can effectively eliminate these unwanted microorganisms and restore the water’s clarity. The process requires careful preparation and attention to safety precautions to ensure successful treatment.

Post-treatment monitoring is just as important. Regular testing and maintenance can prevent future outbreaks of iron bacteria, helping to ensure that well water remains clean and pleasant for everyday use. With a proactive approach, users can enjoy fresh, clear water without the unpleasant effects of iron bacteria.